Erikco World is a leading manufacturer and exporter of Stainless Steel L Channels based in Wuxi, Jiangsu, China. Our L Channels are precision-engineered to meet international quality standards and are widely used in structural, architectural, and industrial applications.

Made from premium-grade 304 or 316 stainless steel, our SS L Channels offer outstanding corrosion resistance, high load-bearing capacity, and versatile fabrication options — making them a reliable choice for contractors, importers, and OEM manufacturers worldwide.

Our Stainless Steel L Channels are ideal Common ApplicationsStructural reinforcement & framing

Machinery frames and equipment racks

Marine and offshore structures

Warehouse racks & supports

Decorative trims and architectural framing

Chemical & food-grade industrial environments

Corrosion-Resistant – Perfect for marine, industrial, and outdoor use

High Structural Strength – Rigid support under stress/load

Aesthetic Finishes – Suitable for visible architectural use

Easy to Machine & Weld – Streamlined for fabrication

Custom Orders Supported – Tailored sizing & finishing

All Stainless Steel L Channels are:

Protected from corrosion during transit

Bundled for easy unloading

Export-packed in wooden crates (optional)

Shipped from nearby ports: Shanghai, Wuxi, Ningbo

We provide:

Commercial Invoice

Packing List

COO

Form E/FTA Documents

Mill Test Certificates

Factory-Direct Prices from Wuxi, China

304 & 316 Grades Available

Equal and Unequal Leg Angles

Custom Lengths, Cuts & Finishes

Exceptional Corrosion Resistance

Export-Ready with Global Shipping

We support both small MOQ orders and bulk international shipments. Our Stainless Steel L Channels are fabricated with tight tolerances and smooth finishes, ready for immediate integration into your project or resale inventory.

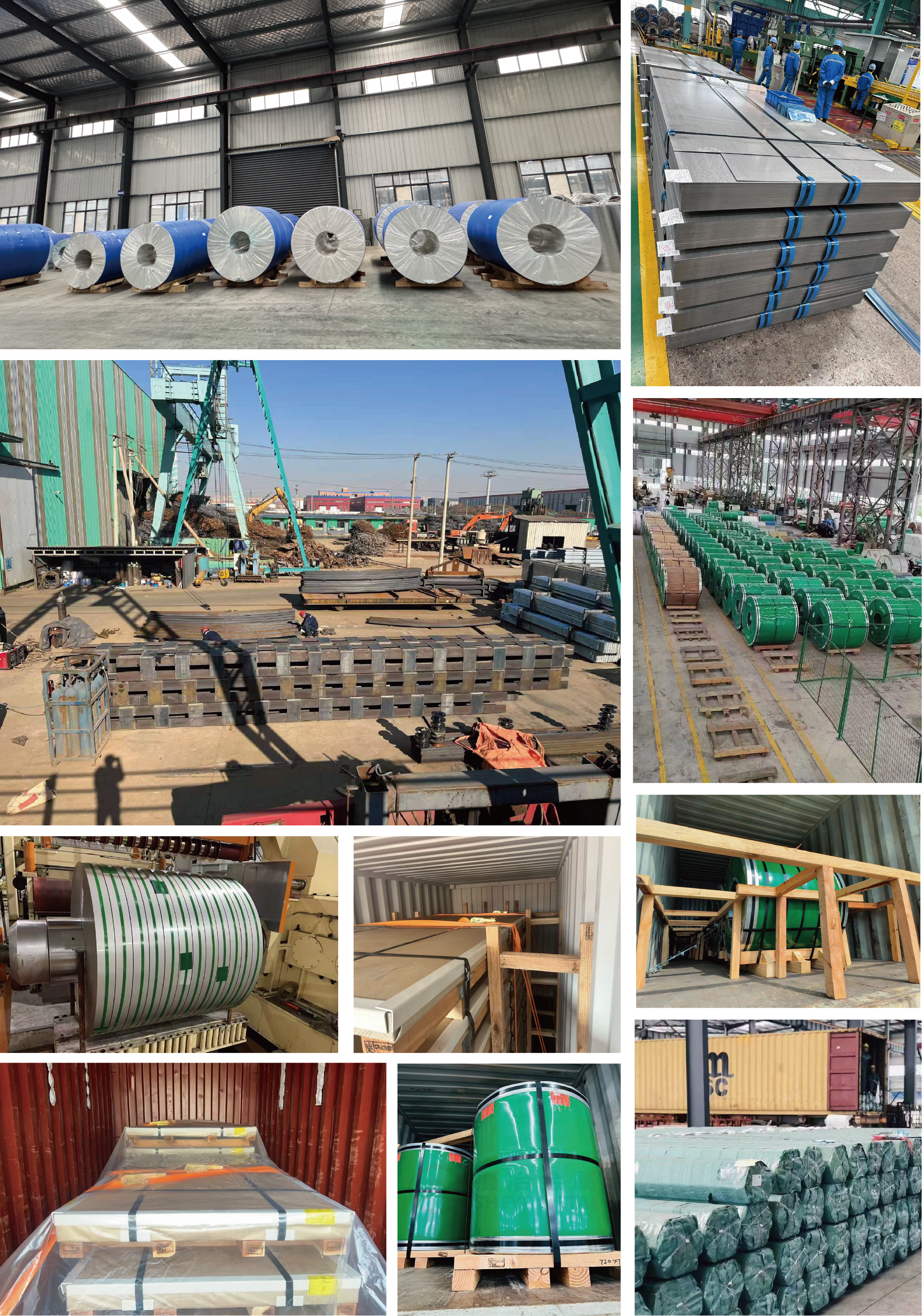

At Erikco World, we take packaging and delivery seriously to ensure that every order reaches our customers in perfect condition. Each product is carefully packed using export-grade protection to safeguard against moisture, rust, and handling damage during transit. Our team follows strict international standards so that whether it is coils, sheets, or structural steel, every item is prepared for safe long-distance shipping.

For delivery, we work with trusted global logistics partners to provide fast and reliable shipping solutions to every region of the world. From the moment an order is confirmed, our logistics team manages the process closely to guarantee smooth customs clearance, accurate documentation, and timely arrival. Whether by sea, land, or air, we make sure your products are delivered securely and on schedule.

With Erikco World, you can rely on professional packaging and dependable delivery that reflect our commitment to quality and customer satisfaction at every stage.

Over 20 Years experience & knowledge international standards, technologicaly changes & industrial systems, we are dedicated to provided seds the best & economical solutions to valued customers.