Quality Assured • Worldwide Delivery • Competitive Pricing

Global Steel Supply Partner

Erikco World specializes in stainless steel, galvanized coils, carbon steel, and structural products with SGS/CE/ISO certifications. Serving industries across Asia, Middle East, and Europe.

Your One-Stop Steel Solution

Reliable Steel, Trusted Worldwide

From coils and sheets to beams and bars, Erikco World delivers precision, strength, and reliability backed by a strong export network.

Industrial Excellence, Global Reach

Steel That Builds the Future

With decades of expertise, Erikco World supplies premium steel materials tailored to construction, manufacturing, and infrastructure projects worldwide.

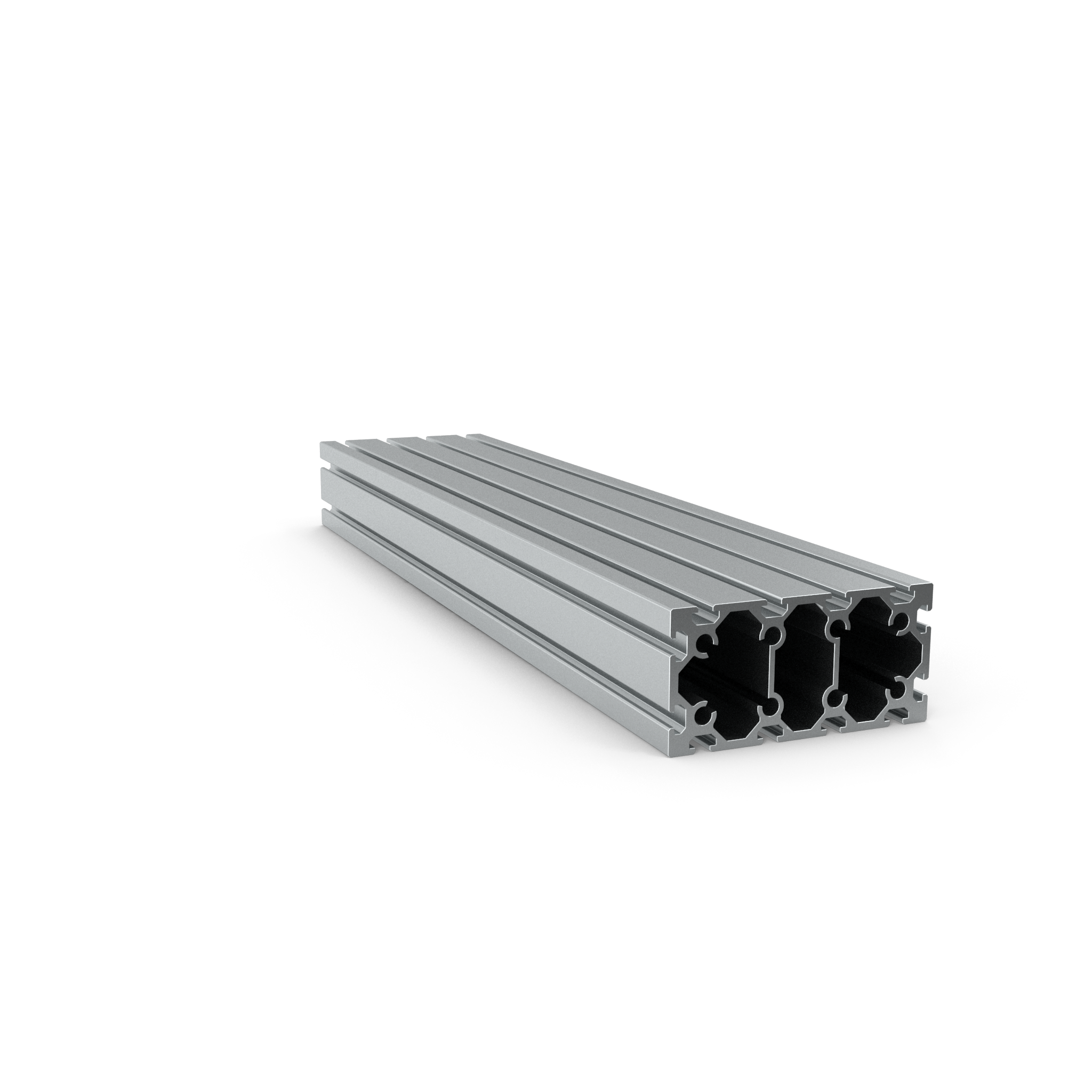

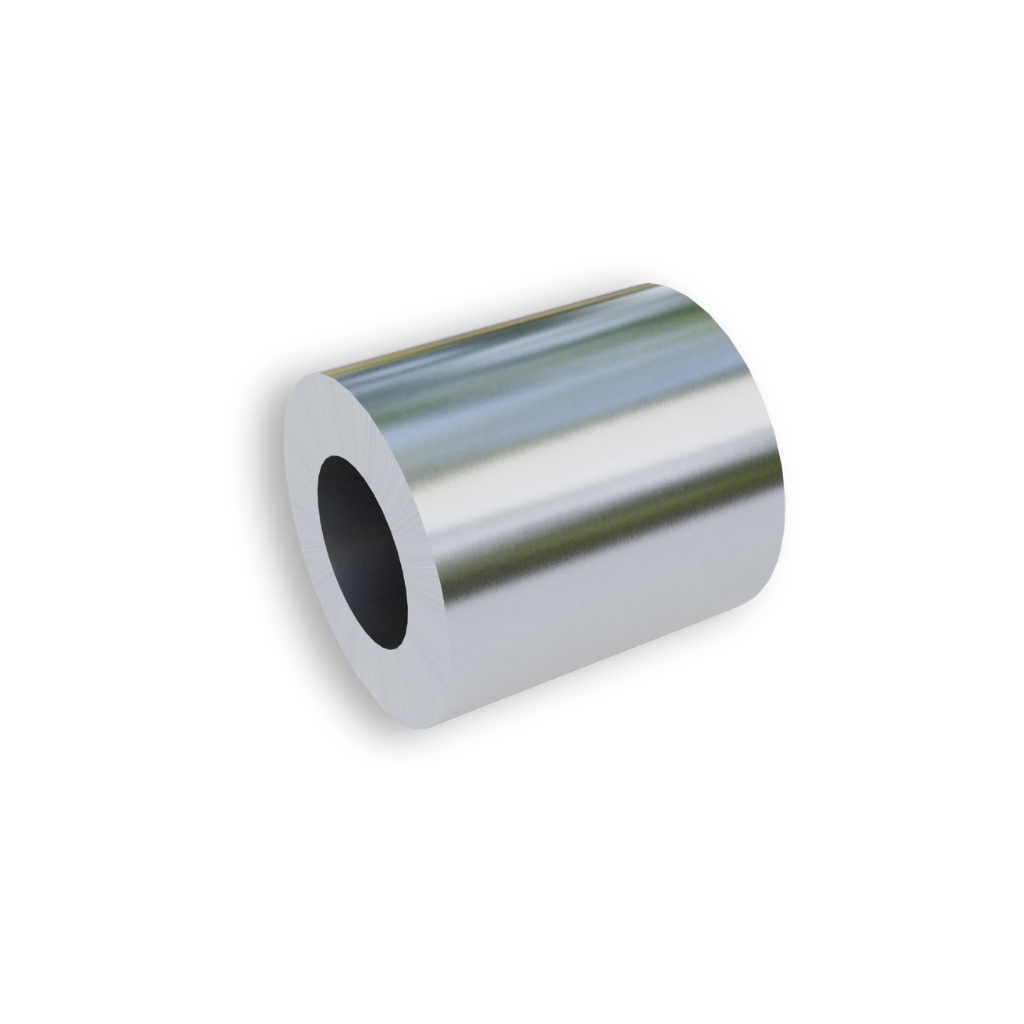

Our Product Categories

Erikco World

About Us

Erikco World was established in Jan 2015. It is a comprehensive large-scale enterprise integrating coating products and various steel processing and production, warehousing, distribution, and foreign trade sales. It is also a national leader in high-strength ultra-thin steel plates. It belongs to the provincial and municipal key export enterprises.

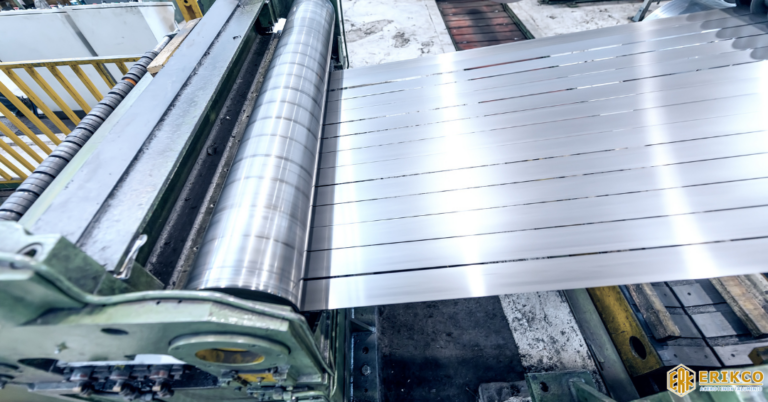

OUR FACTORY

The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets.

Enquiry Now

If you are interested in our products and services, please contact us or leave us a message, we will serve you wholeheartedly.

Contact US

+86-13451671564

Phone

+86 13451671564

sale@erikcosteel.com